full life cycle

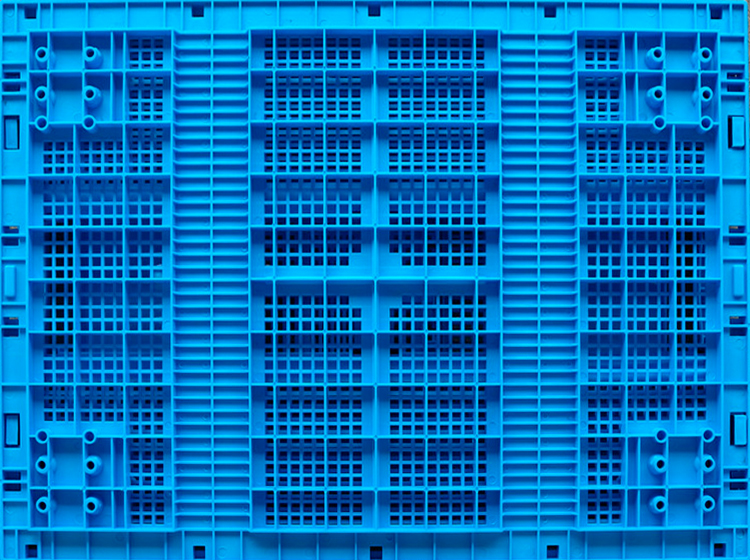

The whole box adopts an all-plastic design, and the parts can be replaced after being damaged; parts without metal, ceramics and other materials can be completely recycled when they are scrapped as a whole, and do not need to be disassembled.

English

English 日本語

日本語 Español

Español 简体中文

简体中文